D-INOX - Drills for Stainless INOX - Cobalt with TIALN coating

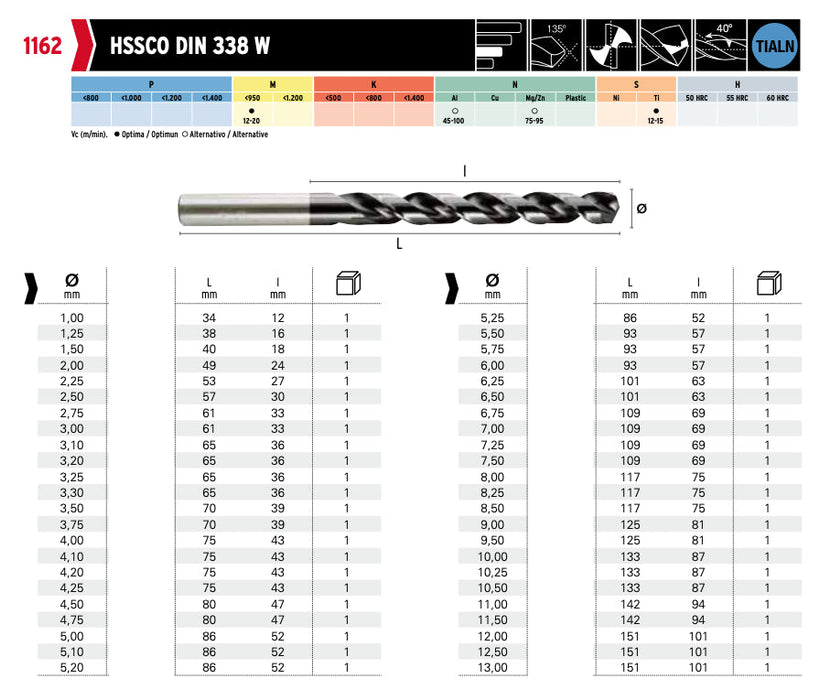

| Κωδικός | Diameter | Cutter | Total | Τιμή | Στοκ | ||

|---|---|---|---|---|---|---|---|

| D-INOX-1 | Ø1 mm | 12 mm | 34 mm | €4,20 | 3 διαθέσιμα | ||

| D-INOX-1.25 | Ø1.25 mm | 16 mm | 38 mm | €5,00 | 1 διαθέσιμo | ||

| D-INOX-1.5 | Ø1.5 mm | 18 mm | 40 mm | €4,00 | 5 διαθέσιμα | ||

| D-INOX-2 | Ø2 mm | 24 mm | 49 mm | €4,00 | 6 διαθέσιμα | ||

| D-INOX-2.25 | Ø2.25 mm | 27 mm | 53 mm | €4,90 | 1 διαθέσιμo | ||

| D-INOX-2.5 | Ø2.5 mm | 30 mm | 57 mm | €4,00 | 10 διαθέσιμα | ||

| D-INOX-2.75 | Ø2.75 mm | 33 mm | 61 mm | €6,20 | 1 διαθέσιμo | ||

| D-INOX-3 | Ø3 mm | 33 mm | 61 mm | €4,40 | 10 διαθέσιμα | ||

| D-INOX-3.1 | Ø3.1 mm | 36 mm | 65 mm | €4,80 | 2-5 εργάσιμες | ||

| D-INOX-3.2 | Ø3.2 mm | 36 mm | 65 mm | €4,80 | 10 διαθέσιμα | ||

| D-INOX-3.25 | Ø3.25 mm | 36 mm | 65 mm | €4,90 | 2-5 εργάσιμες | ||

| D-INOX-3.3 | Ø3.3 mm | 36 mm | 65 mm | €6,10 | 2-5 εργάσιμες | ||

| D-INOX-3.4 | Ø3.4 mm | 39 mm | 70 mm | €6,20 | 2-5 εργάσιμες | ||

| D-INOX-3.5 | Ø3.5 mm | 39 mm | 70 mm | €4,80 | 5 διαθέσιμα | ||

| D-INOX-3.75 | Ø3.75 mm | 39 mm | 70 mm | €5,70 | 2-5 εργάσιμες | ||

| D-INOX-4 | Ø4 mm | 43 mm | 75 mm | €5,50 | 2 διαθέσιμα | ||

| D-INOX-4.1 | Ø4.1 mm | 43 mm | 75 mm | €6,80 | 2-5 εργάσιμες | ||

| D-INOX-4.2 | Ø4.2 mm | 43 mm | 75 mm | €6,80 | 2 διαθέσιμα | ||

| D-INOX-4.25 | Ø4.25 mm | 43 mm | 75 mm | €6,40 | 2-5 εργάσιμες | ||

| D-INOX-4.5 | Ø4.5 mm | 47 mm | 80 mm | €6,40 | 2 διαθέσιμα | ||

| D-INOX-4.75 | Ø4.75 mm | 47 mm | 80 mm | €6,30 | 2-5 εργάσιμες | ||

| D-INOX-5 | Ø5 mm | 52 mm | 86 mm | €6,70 | 5 διαθέσιμα | ||

| D-INOX-5.1 | Ø5.1 mm | 52 mm | 86 mm | €8,50 | 2-5 εργάσιμες | ||

| D-INOX-5.2 | Ø5.2 mm | 52 mm | 86 mm | €7,60 | 2 διαθέσιμα | ||

| D-INOX-5.25 | Ø5.25 mm | 52 mm | 86 mm | €8,30 | 2-5 εργάσιμες | ||

| D-INOX-5.5 | Ø5.5 mm | 57 mm | 93 mm | €8,10 | 5 διαθέσιμα | ||

| D-INOX-5.75 | Ø5.75 mm | 57 mm | 93 mm | €9,20 | 1 διαθέσιμo | ||

| D-INOX-6 | Ø6 mm | 57 mm | 93 mm | €9,00 | 4 διαθέσιμα | ||

| D-INOX-6.25 | Ø6.25 mm | 63 mm | 101 mm | €9,50 | 1 διαθέσιμo | ||

| D-INOX-6.5 | Ø6.5 mm | 63 mm | 101 mm | €10,70 | 5 διαθέσιμα | ||

| D-INOX-6.75 | Ø6.75 mm | 69 mm | 109 mm | €11,30 | 2-5 εργάσιμες | ||

| D-INOX-7 | Ø7 mm | 69 mm | 109 mm | €12,50 | 3 διαθέσιμα | ||

| D-INOX-7.25 | Ø7.25 mm | 69 mm | 109 mm | €14,40 | 2-5 εργάσιμες | ||

| D-INOX-7.5 | Ø7.5 mm | 69 mm | 109 mm | €14,20 | 5 διαθέσιμα | ||

| D-INOX-8 | Ø8 mm | 75 mm | 117 mm | €15,40 | 1 διαθέσιμo | ||

| D-INOX-8.25 | Ø8.25 mm | 75 mm | 117 mm | €16,60 | 2-5 εργάσιμες | ||

| D-INOX-8.5 | Ø8.5 mm | 75 mm | 117 mm | €18,60 | 1 διαθέσιμo | ||

| D-INOX-9 | Ø9 mm | 81 mm | 125 mm | €20,10 | 1 διαθέσιμo | ||

| D-INOX-9.5 | Ø9.5 mm | 81 mm | 125 mm | €22,80 | 1 διαθέσιμo | ||

| D-INOX-10 | Ø10 mm | 87 mm | 133 mm | €25,00 | 5 διαθέσιμα | ||

| D-INOX-10.25 | Ø10.25 mm | 87 mm | 133 mm | €34,90 | 2-5 εργάσιμες | ||

| D-INOX-10.5 | Ø10.5 mm | 87 mm | 133 mm | €29,70 | 1 διαθέσιμo | ||

| D-INOX-11 | Ø11 mm | 94 mm | 142 mm | €31,70 | 2 διαθέσιμα | ||

| D-INOX-11.5 | Ø11.5 mm | 94 mm | 142 mm | €37,10 | 1 διαθέσιμo | ||

| D-INOX-12 | Ø12 mm | 101 mm | 151 mm | €37,10 | 1 διαθέσιμo | ||

| D-INOX-12.5 | Ø12.5 mm | 101 mm | 151 mm | €46,50 | 1 διαθέσιμo | ||

| D-INOX-13 | Ø13 mm | 101 mm | 151 mm | €46,50 | 1 διαθέσιμo | ||

For drilling in stainless steel, or "inox" as it is sometimes called, a cobalt drill or a carbide drill is recommended. These types of drills are made of high-speed steel coated with cobalt or tungsten carbide, which are more durable and suitable for drilling harder materials. Cobalt drills have higher heat resistance, making them ideal for drilling stainless steel, and carbide drills have a harder and more abrasion-resistant material, making them ideal for drilling abrasive materials such as stainless steel.

It is also important to use cutting fluid or lubricant when drilling stainless steel to prevent excessive heat build-up and reduce the risk of the drill breaking or damaging the material. Additionally, slow speeds and high pressure cutting are recommended to prevent material hardening and ensure a clean, accurate hole.

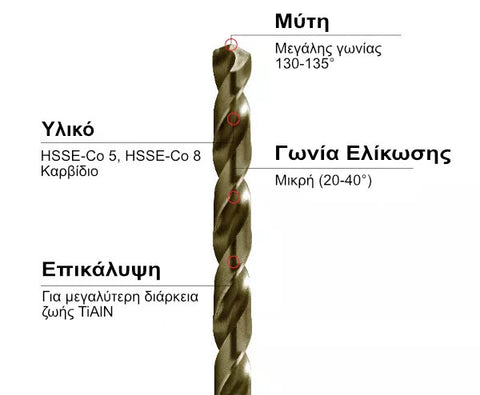

What features should a drill have to cut stainless steel? The following criteria must be met to get a good drilling result.

Stainless steel is a very hard material and therefore difficult to cut. Therefore, the drill should be made of HSSE-Co 5 (5% cobalt content), HSSE-Co 8 (8% cobalt content) or even better solid carbide. Conversely an HSS drill that is too soft will overheat immediately.

Corner of the Nose

The corner of the nose is on the head of the drill. For hard materials such as stainless steel, the angle of the nose must be large and e.g. 130° or 135°. For soft materials, the usual angle is 118°. With a large angle, more of the cutting edge engages the workpiece when drilling. This also means that more force is applied to the workpiece and a higher contact pressure (high feed) is required.

Angle of Helix

The helix angle determines the burr formation process. Small spiral corners are used for hard materials. The helix angle should therefore be small, between 20-40°. Helix angle and nose angle are the determining factors for application in hard or soft materials.

Topping

The TiAlN coating, because it has high heat resistance, is recommended for cutting stainless steel.

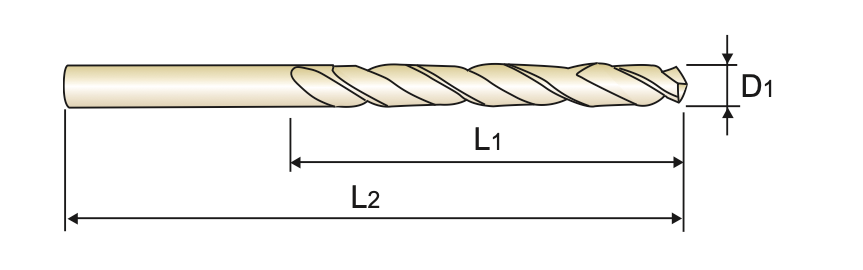

Technical specifications:

- Cobaltio HSSCo - High Speed Steel Cobalt

- Close

- Nose 135º

- Helix 40º

- Cylindrical Stem

- TIALN Overlay

Applications:

TiALN coated cobalt drill special for INOX stainless steels.