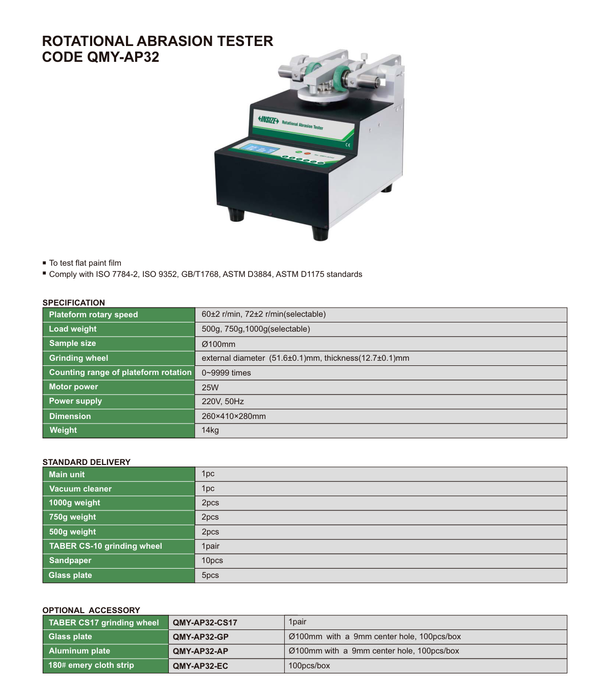

Rotational Abrasion Tester

QMY-AP32

A rotational abrasion tester, also known as a Taber Abraser or Taber Wear Tester, is a device used to assess the resistance and durability of materials to abrasion. It is commonly employed in various industries, including manufacturing, automotive, textiles, and coatings.

The tester consists of a rotating turntable or platform to which the test specimen is attached. The turntable rotates at a fixed speed, while abrasive materials such as grinding wheels, sandpaper, or brushes are applied to the surface of the specimen. The abrasives rub against the material, simulating the wear and tear it may experience in real-world conditions.

The rotational abrasion tester can measure two types of wear: "abrasion resistance," which evaluates the ability of a material to withstand surface damage caused by friction, and "wear index," which quantifies the mass loss of the specimen over a specific test duration.

This testing method is valuable for quality control, product development, and research purposes. It helps manufacturers evaluate the performance and durability of materials, compare different formulations or coatings, and ensure their products meet specific standards or customer requirements.