210 2231624

Micrometers Buyer's Guide

The micrometer it is, together with the caliper, the most widespread precision measuring instrument. It is widely used in mechanical engineering. Its mode of operation is such that the measuring force is always the same. This is achieved by the ratchet which turns in the "air" once the measuring force reaches the limit set by the manufacturer. For this reason, the micrometer is a more reliable measuring instrument than the caliper.

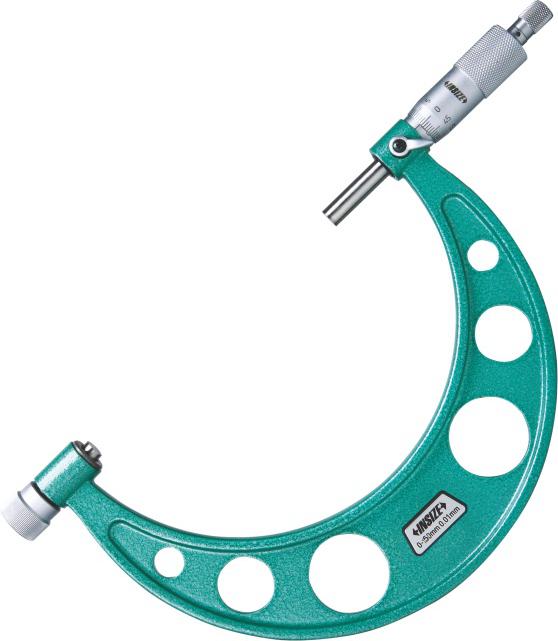

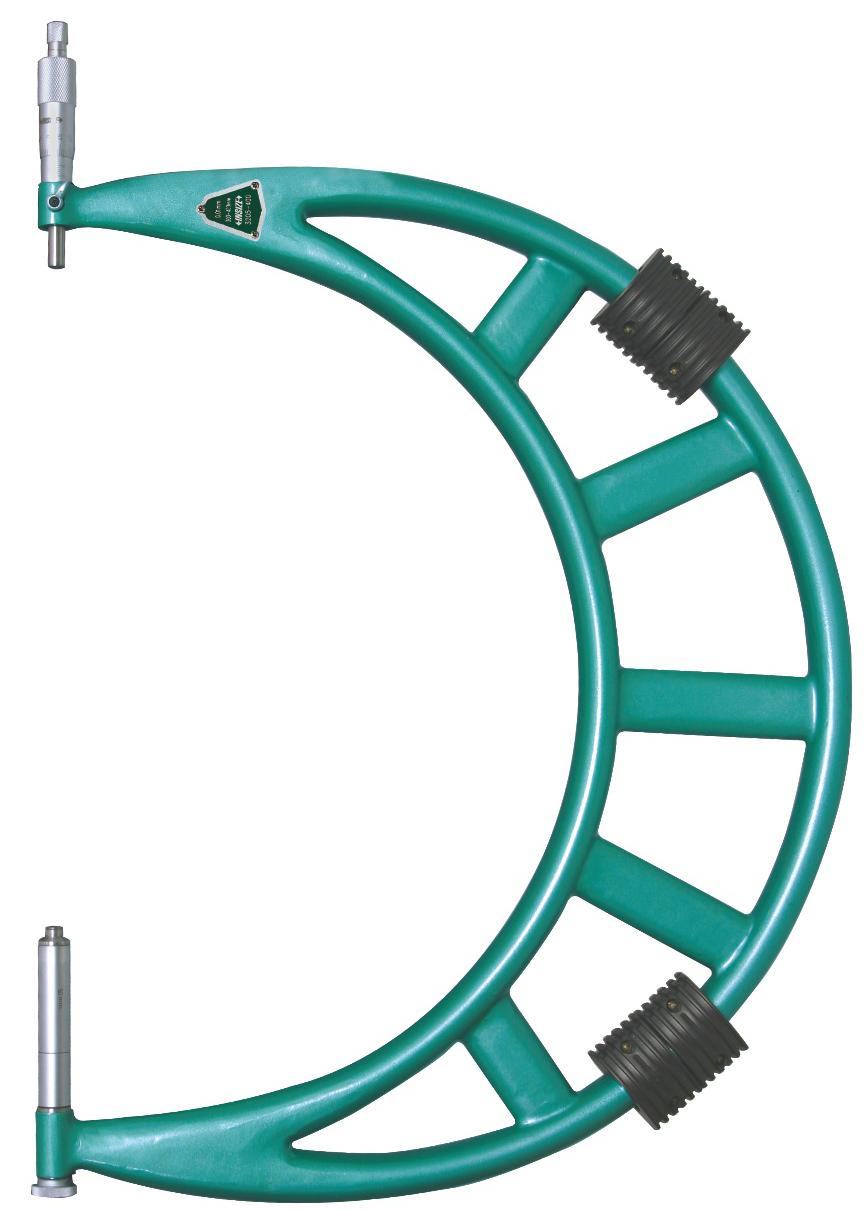

Micrometers are either digital or analog. Then they are divided into external (for external measurements, e.g. axles) and in internally or else a hole. (eg rollers) In addition there is a huge variety for special measurements with various types of soles such as tablets, flares, balls, tips and many others. An important class of micrometers is also of 3 contacts for high-precision measurements on cylinders and holes with great ease and speed. Finally there are the micrometric heads without the ¨horseshoe“ ideal for improvised and specialized measurement needs.

How to measure with the micrometer (0.01mm)

In micrometers of one hundredth of a millimeter (0.01mm) the measurement is done as in the image below.

Vernier micrometer (one micron) (0.001mm)

The vernier scale (3) on the diagram makes it possible to measure to 0.001mm.

As in the calipers we read the vernier to measure the last digit (in this case the microns, μm) by seeing which vernier line coincides with the centimeter line (0.01mm).

Micrometers with counter (0.001mm)

Micrometer expansion due to heat transfer from bare hand.

The graph above shows the expansion of micrometers of different sizes when held with a bare hand. Heat transfer from the hand to the micrometer body can cause quite a large error due to expansion. For this reason some micrometers have a plastic "handle". Otherwise the use of gloves is recommended.

Error due to support address

The table above shows the errors that occur when the micrometer is zeroed with the first mounting method (bottom and middle) but then measurements are made with a different mounting method. Therefore the ideal is to use the same support method during measurement as that used when zeroing the instrument.

Abbe's principle

THE Abbe's principle states that maximum accuracy is achieved when the graphed measurement axis is the same as the measuring axis. This is because the angle "θ" of the moving jaw (of a caliper or micrometer with jaws) causes the displacement "e" which is not measured on the graphed measurement axis.

Micrometer measurement errors.

Various factors can cause measurement errors.- Micrometer screw error.

- Error of flatness & parallelism of soles.

- Excessive measuring force.

Micrometer parallelism check with optical parallels

The parallelism of the anvils can be measured with visually parallel . First we bring the parallel in contact with one tread and then close with the other tread with the normal measuring force. Then we count how many lines are visible. Each line represents a height difference of half a wavelength. (0.32μm for red lines) In the example below the parallelism is about 1μm. 0.32μm x 3 = 0.96μm.

Checking the flatness of the micrometer feet with optical parallels

The flatness of soles can also be measured optically in parallel by counting the number of red lines as seen on the sole with white light. Each line represents a height difference of half a wavelength. (0.32μm for red lines)

General information on using a micrometer

- Careful selection of the type, range, reading, etc. according to the requested application.

- Allow the micrometer and the piece to be measured to reach room temperature.

- We look at the measurement axis with the graphing in a straight line to avoid parallax error.

- We wipe the two measuring feet by passing a paper between them, squeezing them and then gently pulling the paper.

- We use the constant force measurement mechanism correctly.

- When using a micrometer support base we hold it in the center of the shoe. We don't over tighten.

- Be careful not to drop the micrometer on anything. In addition, we do not turn the ratchet with excessive force. In case you think an instrument has been mistreated you can always check it with standard tiles and optical parallels.

Notes on storage

- We avoid permanent exposure to the sun.

- Store in a ventilated place with low humidity.

- We avoid places with a lot of dust.

- When we store it, we make sure to leave a gap of 0.1-1mm between the soles.

- We do not store the micrometer on a stand.