Machine Tap M-Metric - PRIME - for CNC

TM-PRIME

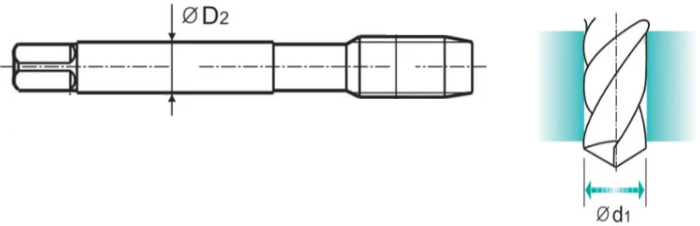

| Κωδικός | Thread | ØD2 (mm) | Ød1 (mm) | Τιμή | Στοκ | ||

|---|---|---|---|---|---|---|---|

| TM-PRIME-M2x0.4 | M2x0.4 | 2.8 | 1.6 | €25,10 | 5-8 εργάσιμες | ||

| TM-PRIME-M2.5x0.45 | M2.5x0.45 | 2.8 | 2.1 | €21,30 | 5-8 εργάσιμες | ||

| TM-PRIME-M3x0.5 | M3x0.5 | 3.5 | 2.5 | €17,40 | 5-8 εργάσιμες | ||

| TM-PRIME-M3.5x0.6 | M3.5x0.6 | 4 | 2.9 | €19,50 | 5-8 εργάσιμες | ||

| TM-PRIME-M4x0.7 | M4x0.7 | 4.5 | 3.3 | €17,70 | 1 διαθέσιμo | ||

| TM-PRIME-M5x0.8 | M5x0.8 | 6 | 4.2 | €18,40 | 1 διαθέσιμo | ||

| TM-PRIME-M6x1 | M6x1 | 6 | 5 | €18,80 | 1 διαθέσιμo | ||

| TM-PRIME-M7x1 | M7x1 | 7 | 6 | €25,50 | 5-8 εργάσιμες | ||

| TM-PRIME-M8x1.25 | M8x1.25 | 8 | 6.8 | €25,90 | 2 διαθέσιμα | ||

| TM-PRIME-M9x1.25 | M9x1.25 | 9 | 7.8 | €30,40 | 5-8 εργάσιμες | ||

| TM-PRIME-M10x1.5 | M10x1.5 | 10 | 8.5 | €31,80 | 1 διαθέσιμo | ||

| TM-PRIME-M12x1.75 | M12x1.75 | 9 | 10.3 | €41,80 | 5-8 εργάσιμες | ||

| TM-PRIME-M14x2 | M14x2 | 11 | 12 | €50,00 | 5-8 εργάσιμες | ||

| TM-PRIME-M16x2 | M16x2 | 12 | 14 | €61,00 | 5-8 εργάσιμες | ||

| TM-PRIME-M18x2.5 | M18x2.5 | 14 | 15.5 | €82,00 | 5-8 εργάσιμες | ||

| TM-PRIME-M20x2.5 | M20x2.5 | 16 | 17.5 | €104,00 | 5-8 εργάσιμες | ||

| TM-PRIME-M22x2.5 | M22x2.5 | 18 | 19.5 | €127,00 | 5-8 εργάσιμες | ||

| TM-PRIME-M24x3 | M24x3 | 18 | 21 | €145,00 | 5-8 εργάσιμες | ||

Description:

High-quality machine Tap from YG-1, a leading cutting tool manufacturer from Korea. It offers reliability, long service life, and excellent cutting performance even on demanding materials. Ideal for productive use, with precise threading and cutting stability, it is a premium choice for professional applications.

Workpiece Materials

Excellent choice for:

- (P1-5) - Common Carbon Steels - (Irons - Black - St37 - ck40)

- (P5-9) - Mild Alloyed Steels - (Steels - Structural Steels)

- (M12) - Ferritic Stainless Steels - (Series 400 - Unpolished, Annealed)

- (M13) - Martensitic Stainless Steels - (Series 400 - Painted)

- (M14) - Austenitic Stainless Steels - (Series 300 - Common INOX)

- (K15-16) - Gray - Cast Irons (2.5-4.0%C , 1.0-3.0%Si)

- (K17-18) - Ductile Cast Irons with Spheroidal Graphite (2.0-2.6%C , 1.1-1.6%Si)

- (N23-24) - Cast Aluminum - Up to 12%Si

- (N26) - Copper Alloys - Leaded Alloys

- (N27) - Copper Alloys - Brass (Cu+Zn)

- (N28) - Copper Alloys - Bronze - Lead-free Alloys

Suitable but not optimal choice for:

- (P10-11) - Strong Alloyed Steels - Tool Steels - (Hard, Difficult Steels)

- (N21) - Common Forming Aluminum - Series (1xxx - 3xxx - 5xxx)

- (N22) - Common Forming Aluminum - Series (2xxx - 6xxx - 7xxx)

- (N25) - Cast Aluminum - Over 12%Si

Cutting Material

-

HSS-PM – Powder Metallurgy High-Speed Steel Improved microstructure and homogeneity compared to common high-speed steels. Offers very good wear resistance, high hardness, and thermal stability.

-

X-Coating (YG-1 Proprietary Coating) – Advanced multi-layer nanostructured coating designed by YG-1. Combines the advantages of TiAlN and AlCrN coatings, offering excellent wear resistance, high thermal stability, and improved resistance to thermal shock.

Technical Specifications:

-

Thread: (M) Metric Standard 60° DIN 13

-

Hole Type: Through holes up to 3xD

-

Form: Form B - Chamfer 4~5 threads

-

Geometry: (Spiral flute) Spiral tap with chip guidance upwards. Produces continuous chip. Used in blind holes.

-

Tolerance: 6HX (DIN 802 part 1, special tolerance, used in materials with high elastic deformation or in forming)

-

Shank: DIN 371 (M2~M10) and DIN 376 (M11~M..)