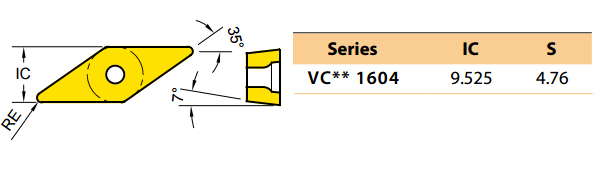

VCGT1604**-AL Inserts for Aluminum

N

VCGT1604**-AL

| Κωδικός | Cutting Depth (mm) | Radius (mm) | Grade | Τιμή | Στοκ | ||

|---|---|---|---|---|---|---|---|

| VCGT160402-AL | 0.05~5.0 | 0.2 | YG10 | €8,20 | 10 διαθέσιμα | ||

| VCGT160404-AL | 0.10~5.0 | 0.4 | YG10 | €8,20 | 17 διαθέσιμα | ||

| VCGT160408-AL | 0.10~5.0 | 0.8 | YG10 | €8,20 | 16 διαθέσιμα | ||

| VCGT160412-AL | 0.10~5.0 | 1.2 | YG10 | €8,20 | 5-8 εργάσιμες | ||

Τιμές χωρίς ΦΠΑ 24%

Machining Materials

- (N) - Non-ferrous materials - Aluminum, Copper alloys, Plastic (Aluminum, Copper alloys, non metallic materials)

Chipbreaker

- (AL) - Geometry for general machining of aluminum and non-metallic materials. Features a particularly large rake angle (rake angle) for smoother chip flow and to avoid built-up edge due to material adhesion on the cutting edge. Suitable for moderate machining of soft (sticky) materials.

Grade

- YG10 – Uncoated for general aluminum machining (N05–N25). Very smooth surface to minimize built-up edge formation.

Feed

- Fn = 0.02~0.30 mm/rev

Cutting Speed

- (N21-30) - Vc=250~800 m/min

Turning inserts from YG1, a leading cutting tool manufacturer from Korea. The choice of the appropriate insert depends on the chipbreaker, i.e., the geometry that helps in breaking and removing the chip, as well as the grade, which describes the microstructure and coating of the insert and directly affects hardness and fracture toughness. The cutting conditions (speed, feed, depth) must be carefully set to achieve maximum tool performance and life.