210 2231624

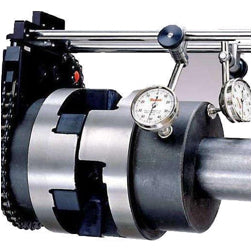

Concentricity Gages

-

0780

07800780 - Bench Center with roller tailstocks

Original price €818,00 - Original price €1.067,00Original price€818,00 - €1.067,00€818,00 - €1.067,00Current price €818,00| /Model Finely ground surface, flatness tolerance according to DIN 876-2 With two adjustable tailstocks Left tailstock with fixed center Rig...

View full detailsΜε παραγγελία

Σχετικές Κατηγορίες

A bench center, also known as a surface plate bench center, is a precision measuring instrument used to check the concentricity and alignment of cylindrical workpieces. It is commonly found in machine shops, tool rooms, and manufacturing facilities where accurate measurement and inspection of cylindrical parts are essential.

The bench center consists of a sturdy base, usually made of cast iron or steel, on which two cylindrical centers are mounted. These centers are precisely aligned and leveled with each other. The centers may be either live centers, which rotate freely, or dead centers, which do not rotate.

The process of using a bench center involves the following steps:

-

Mounting the workpiece: The cylindrical workpiece is placed between the two centers on the bench center's base. The workpiece should be carefully aligned with the centers to ensure accurate measurements.

-

Rotating the workpiece: If the centers are live centers, the workpiece can be rotated manually to check for any wobbling or eccentricity. If the centers are dead centers, a dial indicator or other measuring instruments are used to measure any misalignment.

-

Checking concentricity: By rotating the workpiece, any deviation from true concentricity can be observed. The dial indicator or other measuring instruments provide readings indicating the amount of eccentricity or misalignment.

-

Making adjustments: Based on the measurements, adjustments can be made to the workpiece or machine setup to correct any concentricity errors.

Bench centers are used for various applications, such as checking the roundness of cylindrical parts, ensuring the concentricity of shafts, spindles, or rotating components, and verifying the alignment of lathe chucks or other machine tools.

Overall, bench centers are valuable tools in precision machining and quality control, ensuring the accuracy and performance of cylindrical components in various industries.