TNMG2204**-UF Inserts for Steels - Finishing

P

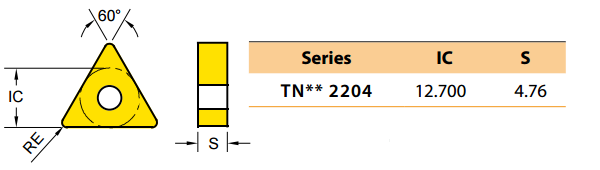

TNMG2204**-UF

| Κωδικός | Cutting Depth (mm) | Radius (mm) | Grade | Τιμή | Στοκ | ||

|---|---|---|---|---|---|---|---|

| TNMG220404-UF-YG3115 | 0.5~4.0 | 0.4 | YG3115 | €7,30 | 21 διαθέσιμα | ||

| TNMG220404-UF-YG3125 | 0.5~4.0 | 0.4 | YG3125 | €7,30 | 14 διαθέσιμα | ||

Τιμές χωρίς ΦΠΑ 24%

Workpiece Materials

- (P) - Steels - Alloy Steels (Steel - Alloy Steel)

Chipbreaker

- (UF) - Geometry specially designed for finishing steels. It features a small rake angle (rake angle) and is available with small cutting radii (RE). Suitable for small cutting depths (Ap) and low feeds (Fn). Ensures excellent surface quality.

Grade

- YG3115 – New grade for high-speed machining of steels (P15–P25). CVD MT-TiCN–Al₂O₃ coating. Ideal for mass production with stable tool life and minimization of built-up edge formation.

- YG3125 – First choice for steel machining (P15–P35). New grade with high heat resistance and interrupted cutting capability. CVD MT-TiCN–Al₂O₃ coating with final TiN layer for wear control and easy recognition of worn edges. Surface treatment reduces built-up edge formation and improves chip evacuation. Ideal for continuous and interrupted cuts in mass production applications.

Feed

- Fn = 0.05~0.25 mm/rev

Cutting Speed

- (P1-5) - Vc=180~500 m/min

- (P5-9) - Vc=170~450 m/min

- (P10-11) - Vc=60~300 m/min

Turning inserts from YG1, a leading cutting tool manufacturer from Korea. The choice of the appropriate insert depends on the chipbreaker, i.e., the geometry that helps in breaking and removing the chip, as well as the grade, which describes the microstructure and coating of the insert and directly affects hardness and fracture toughness. The cutting conditions (speed, feed, depth) must be carefully defined to achieve maximum performance and tool life.