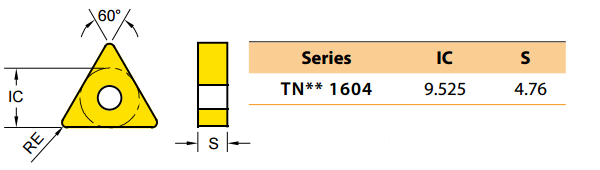

TNMA1604** Inserts for Cast Iron - Heavy Cuts and Roughing

K

TNMA1604**

| Κωδικός | Cutting Depth (mm) | Radius (mm) | Grade | Τιμή | Στοκ | ||

|---|---|---|---|---|---|---|---|

| TNMA160404-YG1010 | 0.5~5.0 | 0.4 | YG1010 | €5,90 | 19 διαθέσιμα | ||

| TNMA160408-YG1010 | 1.0~5.0 | 0.8 | YG1010 | €5,90 | 5-8 εργάσιμες | ||

| TNMA160408-YG3010 | 1.0~5.0 | 0.8 | YG3010 | €5,00 | 38 διαθέσιμα | ||

| TNMA160412-YG1010 | 1.5~5.0 | 1.2 | YG1010 | €5,90 | 5-8 εργάσιμες | ||

Τιμές χωρίς ΦΠΑ 24%

Machining Materials

- (K) - Cast Irons - Grey Cast Iron (Cast Iron)

Chipbreaker

- (..MA) - Designed for machining brittle materials such as cast irons and coated steels. It has no geometry on the cutting edge. Suitable for heavy roughing **(roughing) in cast irons and light machining in coated steels.

Grade

- YG1010 – Ideal choice for cast iron (K05–K15). CVD TiCN–Al₂O₃ coating with special post-treatment for increased coating chipping resistance.

Feed

- Fn = 0.15~0.50 mm/rev

Cutting Speed

- (K15-16) - Vc=300~450 m/min

- (K17-18) - Vc=120~350 m/min

Turning inserts from YG1, a top cutting tool manufacturer from Korea. The choice of the appropriate insert depends on the chipbreaker, i.e., the geometry that helps break and remove the chip, as well as the grade, which describes the microstructure and coating of the insert and directly affects hardness and brittleness. The cutting conditions (speed, feed, depth) must be carefully set to achieve maximum tool performance and life.